Labworks International Modular Manufacturing Facility provides prefabricated environmental rooms, test chambers, airlocks, classified cold/warm rooms, and pass-throughs. These units are designed, assembled, and tested in Labworks’ facility prior to shipment to clients across North America.

Labworks Prefabricated Modular Facility

204 Mapleview Dr. W, Unit 2

Barrie, ON L4N 9E8

Prefabrication allows assembly work to occur in an ideal environment where tools, equipment, and testing apparatuses are available to ensure the highest quality product. Factory acceptance testing is completed before shipment to minimize installation time at the site.

At Labworks, we offer virtual witnessing of FAT through camera and data connections to the plant. Units include certifications by UL, CSA, ASTM and FM where applicable.

Products

Environmental Rooms

An environmental room allows complete control over temperature and humidity to create a known, stable environment. This is commonly used for a wide variety of manufacturing and pharmaceutical/ life science research applications, such as:

- Quality control laboratories

- Dry rooms

- Incubators

- Drug or research material storage

At Labworks, we offer critical temperature/ humidity environmental rooms that are fully assembled and factory tested prior to shipment. Depending on the dimensions, rooms can be shipped, assembled, or knocked down and reassembled on site.

Our designs are flexible and can be made to suit nearly every facility, no matter how big or small. We will work with you to create an environmental room that fits your specific needs and requirements.

Air Locks

Available in uPVC or stainless steel finishes, Labworks offers a full range of air lock sizes. A variety of doors are also available, from rapid roll-up to swing to sliding. Our modular airlocks can be fully prefabricated and tested for the standard required at the site.

Classified Cold/Warm Rooms

Modular classified cold and warm rooms offer precision temperature control and cleanroom-grade contaminant control. They are often needed in pharmaceutical and life sciences industries for applications such as:

- GMP storage

- Pharmaceutical drug storage

- Biological culture incubation

- Stock storage

At Labworks, we support our clients with detailed assistance at every stage of the project, from design through to implementation.

Revit Modelling

Our classified cold and warm rooms are made to suit your specific requirements with detailed Revit models. These models provide a complete rendering of the space, with all necessary services, clearances, and equipment sizing details. Every cold and warm room is custom designed.

Advanced Materials

Our environmental cleanrooms are specifically constructed with materials selected for their performance characteristics in life science applications. Room surfaces are available in uPVC with cold-welded seams or 304/316 stainless steel. We also offer a full range of accessories including powered doors, counters, racking, electrical services, and more.

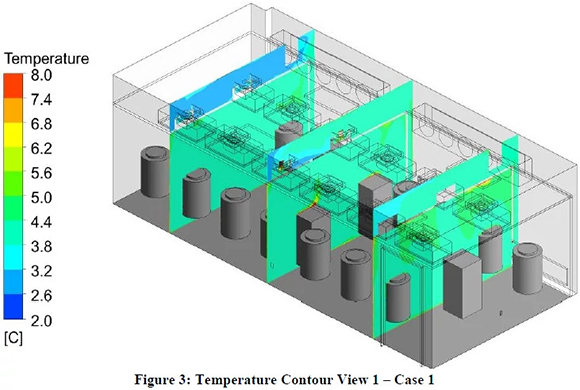

Performance

Pre-manufactured at Labworks’ facility, these units can be pre-validated for temperature and humidity control and uniformity. We guarantee the performance of our rooms and can provide independent certification or validation testing with each room.

Pass-Throughs

Pass-throughs of all dimensions are fabricated and tested prior to shipment to locations. For active pass-throughs the units are fully factory tested and ready for installation at the site.

Benefits

Prefabricated units allow all assembly work to occur in ideal conditions with tools, equipment and testing apparatuses to ensure the highest quality product. Factory acceptance testing can be completed prior to shipment, improving the speed of installation at the site. Labworks offers virtual witnessing of FAT through camera and data connections to the plant. Units include certifications by UL, CSA, ASTM and FM where applicable.

how prefabricated products

can help your project.