Meeting Stringent Temperature Control Without Exceeding Costs

When it comes to precision-controlled environments, balancing performance and budget is often a challenge. A recent project delivered by Labworks put our expertise to the test: designing a -20°C controlled environment with tighter temperature stability than industry standards—all while staying within the client's budget. Labworks could have proposed changing the design to a zero-deviation freezer (zero or negligible temperature spike during defrost) which is not uncommon in the industry but this would have been extremely costly. Given the ultimate product specification limits of ±5°C it would also have been unnecessary to provide a freezer that maintained less than +/-1C during defrost. The key through all of this was to meet our customers expectations without adding unnecessary costs or complexity.

Understanding the Challenge

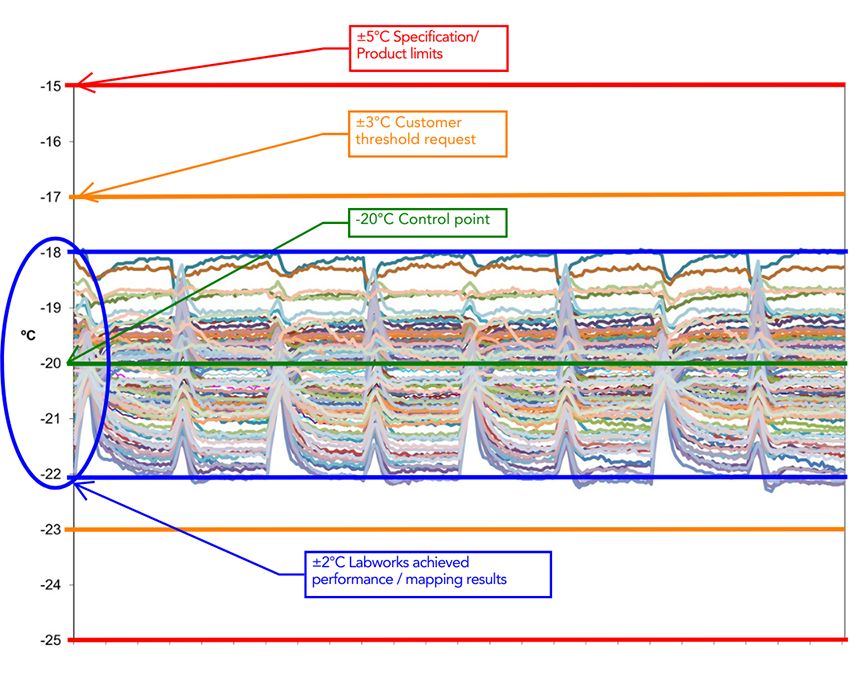

The standard for this temperature-controlled Freezer allowed for a product deviation tolerance of ±5°C, but this particular client requested significantly stricter temperature control at ±3°C to stay within their pre-action alarm thresholds. This level of precision typically requires costly upgrades, making it difficult to stay within budget. Our goal was clear: develop a system that could deliver enhanced stability without adding unnecessary costs.

Our Solution: Engineering Excellence & Cost Efficiency

At Labworks, we believe that high-performance solutions shouldn’t come at the cost of financial feasibility. Our approach focused on:

- Optimizing refrigeration system components for better efficiency and reliability.

- Refining control mechanisms to maintain consistent temperatures.

- Maximizing energy efficiency to lower operational costs over time.

- Leveraging our industry expertise to design a system that exceeded the client’s expectations without exceeding their budget.

The Results: Outperforming Expectations

By implementing these strategies, Labworks International successfully delivered a solution (±2°C) to meet the customer requests (±3°C) and further exceed the Specification limits (±5°C)

The Impact: More Than Just Stability

Beyond achieving better-than-expected temperature control, our approach delivered additional benefits:

- Enhanced product protection with reduced temperature fluctuations.

- Increased energy efficiency leading to long-term cost savings.

- Budget-conscious execution ensuring the client stayed within financial limits.

Why This Matters

Achieving tighter temperature control in cold storage environments is critical for industries that rely on stability, such as pharmaceuticals, healthcare, and research. Labworks International’s ability to engineer cost-effective, high-precision solutions demonstrates that exceeding expectations doesn’t have to mean exceeding budget.

Conclusion: Precision Without Compromise

This project showcases Labworks International’s commitment to innovation, efficiency, and client success. By combining technical expertise with strategic cost management, we continue to set new standards in precision-controlled environments.

If your facility requires advanced environmental control solutions, contact Labworks International today to see how we can help optimize performance and deliver a solution that meets your needs.

Leave A Comment